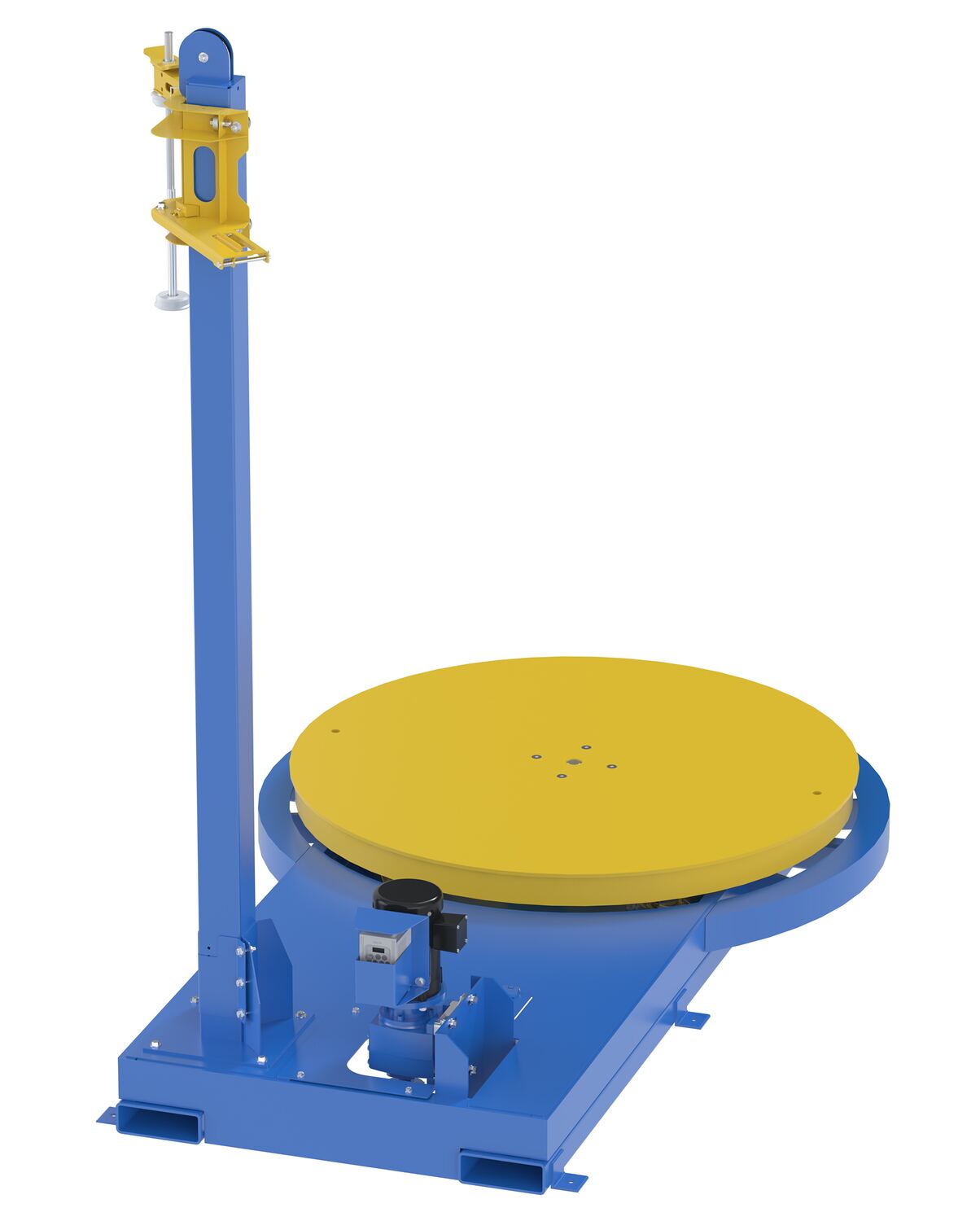

Performance problems can be minimized through timely stretch wrap machine repair and routine maintenance.

Performance problems can be minimized through timely stretch wrap machine repair and routine maintenance.

Blog Article

Professional Tips to Guarantee Successful Stretch Wrap Maker Fixing Practices

When it pertains to extend cover maker repair services, understanding the common issues that can occur is crucial. You'll wish to be furnished with the right devices and a clear troubleshooting procedure to take on troubles properly. Regular upkeep can not be overlooked either, as it plays an important duty in avoiding bigger problems down the line. Allow's explore these essential locations to guarantee your fixing methods are as reliable as possible.

Comprehending Common Stretch Wrap Equipment Issues

When you make use of a stretch wrap device regularly, it's important to acknowledge common concerns that can develop. One constant issue is irregular stress in the film, which can lead to loosened or overly tight covers. You'll desire to inspect the tension settings regularly to verify they're calibrated appropriately. One more usual concern is movie sticking or tearing, frequently brought on by incorrect loading or worn-out components. If you observe this, evaluate the movie course and change any broken parts. Additionally, expect error messages or uncommon noises throughout operation; these can indicate mechanical malfunctions. Obstructing is another headache, typically stemming from particles or misaligned rollers. Regularly clean the equipment and confirm all parts are lined up to stop this. By staying in advance of these concerns, you can maintain your stretch cover machine running smoothly and effectively, decreasing downtime and maintaining performance in your procedures.

Essential Tools for Reliable Repair Work

To effectively repair a stretch wrap maker, having the right tools on hand is crucial. These will help you deal with most mechanical concerns.

Don't forget safety and security equipment, such as handwear covers and safety goggles, to shield yourself while working. An excellent flashlight is very important, as well, as it assists light up limited spaces where you could require to check elements.

Additionally, maintain a toolkit with spare components like belts, rollers, and integrates. These can conserve you time during repairs, allowing you to replace damaged components instantly. A solution manual details to your maker will certainly provide support and schematics, making repairs much more uncomplicated. With these necessary devices, you'll be well-equipped to manage any kind of repair work difficulty that comes your way.

Step-by-Step Troubleshooting Overview

When repairing your stretch cover equipment, it's vital to begin with a review of usual concerns you could encounter. By utilizing the best diagnostic tools, you can rapidly identify the origin of the issue. Allow's stroll via a detailed overview to get your maker back up and running effectively.

Typical Concerns Review

While stretch wrap equipments are necessary for reliable product packaging, they can run into an array of problems that interrupt operations. One typical problem is inconsistent movie stress, which may result in loosened or extremely limited wraps. If you notice this, check the stress settings and make certain the movie is packed correctly. Another concern is film tearing during the wrapping process; this often originates from boring cutting blades or inappropriate film alignment. Regularly examine and change blades as required. Additionally, if the device will not start, verify that all safety and security buttons are engaged and the power supply is functioning. Be sharp for unusual sounds, which could show mechanical wear that demands prompt interest. Dealing with these concerns quickly can save you time and sources.

Analysis Devices Usage

Efficient troubleshooting starts with the appropriate analysis tools available. Begin by gathering crucial tools like multimeters, thermal cameras, and stress evaluates. stretch wrap machine repair. Each device offers a specific function in recognizing concerns

First, make use of a multimeter to check electrical links and warranty power moves correctly. Next, employ a thermal video camera to identify overheating parts, which can indicate failures. Make use of a stress scale to check pneumatic systems for leakages or inconsistencies.

As you evaluate, document your searchings for. This document aids track reoccuring troubles and simplify future repairs. Don't be reluctant to consult your machine's manual for specific repairing actions related to the version. With these devices and a methodical method, you'll efficiently diagnose and settle machine concerns.

The Importance of Normal Maintenance

Regular maintenance is essential for maintaining your stretch wrap machine running efficiently and effectively. By organizing preventative upkeep, you can catch possible problems before they intensify, saving you money and time. Remaining on top of maintenance intervals warranties your equipment continues to be in leading shape and minimizes unanticipated downtime.

Preventative Maintenance Conveniences

When you prioritize preventative upkeep for your stretch wrap machine, you not only expand its life expectancy yet likewise improve its performance. Normal checks aid determine possible problems prior to link they escalate right into expensive repair work. By maintaining components tidy and lubricated, you ensure smoother procedure, which can result in much better covering quality and lowered material waste.

Moreover, a well-maintained device operates with fewer interruptions, reducing downtime in your production line. Embrace preventative maintenance, and watch your procedures prosper.

Arranged Maintenance Intervals

Although it may be appealing to skip maintenance checks, sticking to scheduled upkeep periods is crucial for maintaining your stretch cover maker running smoothly. Regular upkeep aids you determine prospective problems before they rise right into expensive repair work. By adhering to an established timetable, you ensure that all vital elements receive the focus they require, stopping unforeseen breakdowns and downtime.

Make it a practice to log upkeep tasks and track performance trends. This information can lead future upkeep and help you fine-tune your procedures. Don't forget to consult your equipment's manual for details recommendations regarding upkeep intervals. Spending time in arranged upkeep not just extends your equipment's life expectancy but additionally enhances performance in your Clicking Here operations. Keep positive, and your stretch wrap maker will thanks!

Safety Protocols During Fixing Work

To secure a risk-free fixing setting, it is vital to comply with well established safety and security protocols. Always use the proper individual safety tools (PPE), including gloves, safety goggles, and steel-toed boots. Before starting any type of job, confirm the maker is powered down and secured out to stop accidental startups. Familiarize yourself with the machine's technological documentation and safety warnings; this knowledge can prevent dangerous mistakes.

Training and Ability Advancement for Technicians

Efficient training and skill growth for professionals are essential in making certain effective stretch wrap equipment repair services. You need a strong understanding of the equipment's elements and how they work together. Start with hands-on training, allowing you to acquaint yourself with the devices and its maintenance demands. Make use of online sources, handbooks, and maker guidelines to grow your knowledge.

Motivate constant education by going to workshops and workshops concentrated on the most recent modern technologies and repair techniques. This keeps you upgraded on industry trends and helps you embrace best techniques. Coupling knowledgeable professionals with newcomers cultivates a finding out atmosphere where skills can be shared and developed.

Finally, execute a mentorship program to assist much less skilled professionals, guaranteeing they get the self-confidence and experience required for reliable repairs. Purchasing training and ability advancement not just boosts repair work quality however likewise boosts the general performance of your operations.

When to Seek Professional Aid

Recognizing when to look for professional aid can save you time and protect against additional damages to your stretch wrap equipment. If you discover persistent concerns like uncommon sounds, inconsistent wrapping, or mistake messages that you can't repair, it's best to employ a specialist. Do not disregard minor problems, as they can escalate right into pricey fixings if left unaddressed.

Furthermore, if my review here you have actually already attempted repair services but have not seen improvement, it's a clear indicator that specialist treatment is needed. Servicing complicated systems without the appropriate proficiency can result in more substantial failures.

Often Asked Questions

How Typically Should Stretch Wrap Machines Be Serviced?

You need to service stretch wrap machines every six to twelve months, depending on usage. stretch wrap machine repair. Normal maintenance prevents break downs, enhances efficiency, and extends the maker's lifespan, guaranteeing you get the most out of your financial investment

What Are the Indications of a Stopping Working Stretch Wrap Maker?

You'll see a stretch wrap machine is failing if it creates inconsistent wraps, makes uncommon noises, or shows mistake messages. Furthermore, regular jams or slow-moving operation can show underlying concerns requiring instant focus and repair.

Can I Repair My Device Without Prior Experience?

You can attempt to fix your equipment without previous experience, yet it's risky (stretch wrap machine repair). You could face difficulties understanding parts or detecting issues. Think about seeking guidance or expert assistance to prevent further damages and assurance reliable fixings

What Is the Ordinary Life Expectancy of a Stretch Wrap Maker?

The average lifespan of a stretch cover device is typically around 5 to one decade, depending on usage and maintenance. Normal maintenance can prolong its life, ensuring you obtain the most out of your investment.

Exist Certain Brand Names Known for Better Integrity?

Yes, some brand names like Aetna and Lantech are understood for their reliability. You'll locate that buying well-reviewed machines typically causes less maintenance problems and longer lifespan, conserving you time and expenses in the lengthy run.

Final thought

By prioritizing maintenance, making use of the right tools, and complying with a systematic troubleshooting guide, you can enhance your stretch cover equipment repair work techniques. Bear in mind, regular inspections and paperwork assistance capture problems early, while sticking to safety and security methods maintains you and your group risk-free.

Report this page